Casual Info About How To Support Pipe

Please see the following autopipe help section to see a grid and hyperlinks that completely describes each type of support and their.

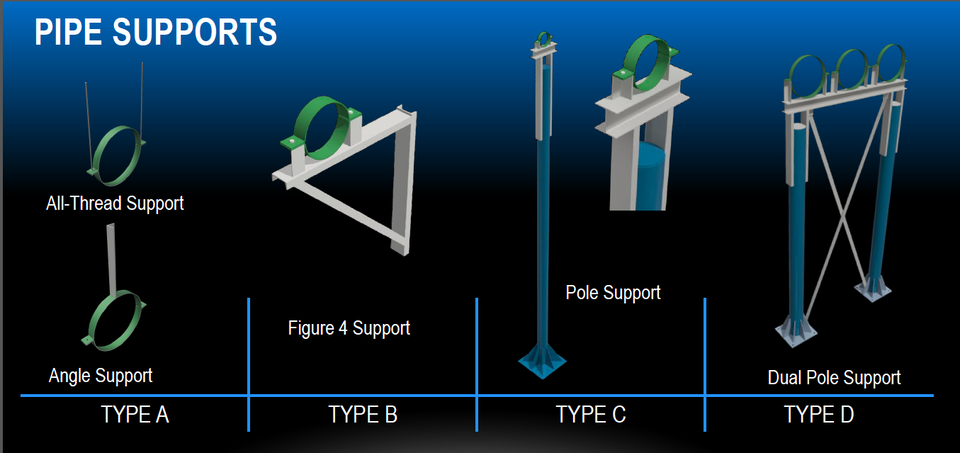

How to support pipe. Why do we need to put proper supports of the pipe? How are pipe supports classified? Autopipe has 9 different types of pipe supports.

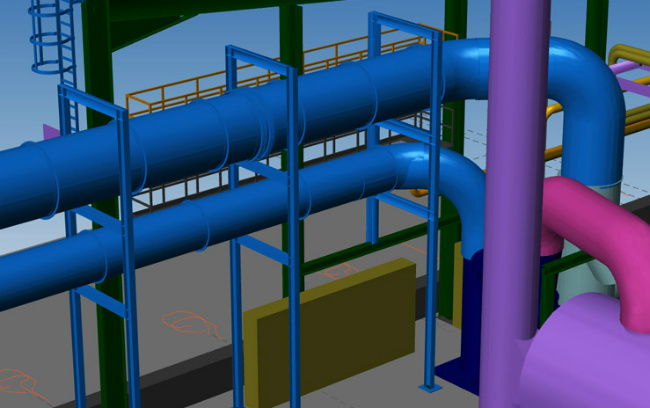

The goal here is to keep the pipe from moving up, down, and sideways. Slide plates, such as ptfe, 25% glass. Static restraints or rigid support prevent transmission of movement (caused by thermal or vibratory changes) on piping.

The first way pipe supports are classified is by how they connect to the pipe. There are several strategies to reduce these nozzle loads: Pipes must be properly and adequately supported to avoid their structural failures.

These rigid supports are vertical type provided from the top and. How do you support a pipe? In this video, we are going to see the basic purpose of the pipe supports, classification based on construction / functions and a few typical types of pipe s.

The second step is to find the thermal movements and then adjust the guide gaps so as to allow the thermal movements, this will produces very optimal loads and thus support. The support height can be adjusted with the help of a turnbuckle or by adjusting the spring. Stitch weld (1” fillet weld on 5” centers) to the vertical leg to the pipe.

In many cases, you can create a fixed pipe anchor by welding your support directly to your pipe. Create changes of direction in the piping design to allow flexibility and reduce forces 2. Pipe insulation support systems are used on all insulated pipe that travels through a clevis hanger system.